Failure in distribution transformers is one of the major cause of concern in Indian power distribution system. One of the main cause of failure of distribution transformers is prolonged overloading and loss of life due to thermal degradation of insulation. Therefore, it is necessary to monitor hotspot temperature of transformer continuously at all loading conditions. This temperature depends on the load loss and temperature of external cooling medium.

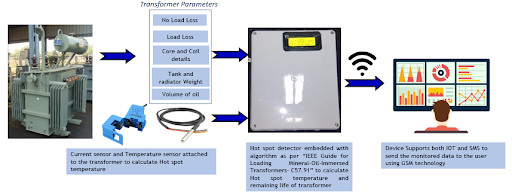

ERDA has developed a hotspot detector for distribution transformers. The hotspot detector has been developed as per “IEEE Guide for Loading Mineral Oil Immersed Transformers -C57.91”. This invention uses indirect method and involves the use of ambient, top oil, bottom oil temperatures and PU load to identify hot spot temperature of the distribution transformer during service condition, with the help of which remaining life of the transformer is also estimated.

This device when installed with transformer, results in an effective and non-destructive asset management tool, which also leads to condition based maintenance instead of routine regular maintenance of the distribution transformer fleet.

This device prevents transformer failure by continuously monitoring. By this, rate of failure of distribution transformers can be reduced which saves direct or indirect loss cause to the industries due to power failure caused by distribution transformers.

Advantages of Innovation as compared to present technology

The other method to detect the hot spot temperature of the transformer requires more number of optical fiber sensors to be placed in between the windings. So the installation is difficult and one needs to be careful due to fragile nature of the sensors. This installation is to be carried out at manufacturing stage and is difficult to install at a later stage. Due to more number of sensors, the cost of the device is very high. ERDA’s Innovation device uses less number of sensors (only 3 numbers) that are to be connected external of the transformer.

Functionality of the Innovation

The developed innovation serves following purposes:

- Calculate the Hot spot temperature of the transformer

- Calculate Remaining Life Period of the transformer

Figure 1: Model overview

Distinctive features of the Innovation

- Retrofit solution – can be fitted in installed distribution transformer

- Enables remote monitoring of transformer fleets – monitoring from any location in world

- Portable – small in size and irrelevant to the different rating of the transformer, 250mm (L) x 250mm (W) x 80mm (H)

- Scalable – can be used for any rating transformer by selecting the current sensor rating

- Inexpensive

- Cost effectiveness

- Easy installation

- Distributed sensors are not required

- Reliable & robust system

Product information

- Current Sensor –Senses the transformer load at LV side to calculate the Per unit load

- Temperature Sensor – Senses the temperature of Transformer Top Oil, Bottom Oil and Ambient Temperature for Hot Spot Calculation

Measurement range

- Current Measurement range – 0-30Amps (Changeable to the requirement)

- Temperature sensor range – -55°C to 145°C

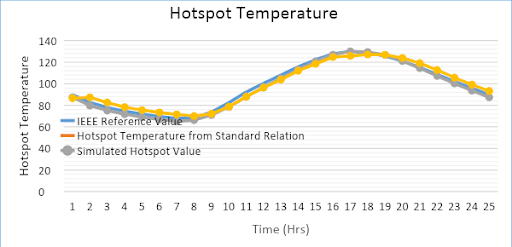

IEEE C57.91 - Algorithm validation

Figure 2 shows the accuracy of the simulation result in compare with the IEEE reference value.

Figure 2: Simulated Hot spot value vs IEEE Hot spot temperature and Hot spot calculated from standard relation

ERDA's

Leadership Team

Dr. Satish Chetwani

Director

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

01.Dr. Uday Puntambekar

Asst. Director & Head of Division Mechanical and Insulating Materials, Rajahmundry, Purchase

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

02.Mr. Rajib Chattopadhyay

Sr. Manager & Head of Division PETE II (Impulse, Cable, CT-PT, Calibration), Rabale, Narol, ERDA North, Maintenance, (Electrical & Civil)

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

03.Mr. Anil Khopkar

Asst. Director & Head of Division Business Development & CRM, Corporate (Accounts & Finance, P&A, HR)

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

04.Mr. Anil Aswani

Asst. Director & Head of Division SEC (Third Party Inspection, Energy Meter, EMI/EMC, Appliance, Lamps & Luminaries, Motor & pumps, Power Systems)

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

05.Mr. Yashinkhan Pathan

Sr. Manager & Head of Division PETE I (Transformers, Switchgear, Short Circuit – Makarpura & Savli)

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

06.ERDA's

VISION

An Internationally Renowned Laboratory and Center of Excellence in R&D for Electrical Industries and Utilities.

ERDA's

MISSION

To Achieve Excellence by Virtue of Competence through R&D, Testing, Calibration, Training and Information Dissemination to Improve Quality and reduce the cost of Equipment, Materials and Services for Electrical Industries, Utilities and Users of Electricity.

ERDA's

VALUES

- Attitude to Excellence

- Dedication to Satisfy Customer Through Competitive Quality Services in Minimal Lead Time

- Confidence in Integrity of Results

- Loyalty & Pride for the Organization

- Work as Family

- Respect Dignity / Potential of Individuals

- Motivate Each Other

- Strengthen Membership and Industry Links

- Develop Linkages with Foreign Research Organizations

- Marketing at International Level

ERDA's

Middle Management Team

| Name of Employee |

|---|

| Mr. Mehul Patel Sr. Manager HR |

| Mr. Pratik Shah Asst. Manager Accounts & Finance |

| Mr. Pranav Parikh Dy. Manager Business Development |

| Mr. Shailesh Patel Sr. Manager Cables, CT-PT, Capacitors & PD |

| Mr. Ravi Nandwana Sr. Engineer CT-PT & Capacitors |

| Mrs. Vidya Kapse Dy. Manager Customer Relationship Management |

| Mr. Puran Gajera Dy. Manager EMI/EMC |

| Mr. Nitin Chitte Asst. Manager Impulse – Makarpura |

| Mr. Anil Solanki Sr. Manager Information Technology |

| Mr. Jaydeep Sheth Dy. Manager Liquid Dielectric |

| Mr. Ravi Singh Dy. Manager Motors & Pumps, Solar Pump & Converters |

| Mr. Anil Suthar Dy. Manager Mechanical |

| Mr. Bhavesh Vasiyani Manager Non Destructive & Energy Management |

| Mr. Mitesh Prajapati Sr. Engineer Quality System |

| Mr. Sandeep Soni Manager Short Circuit 3– Savli |

| Mr. Amar Shah Dy. Manager Third Party Inspection |

| Mr. Asheesh Dhaneria Manager TM5(A) NPT Electronics, TM5 (B) NPT Electrical |

| Mr. Munaf Patel Manager Short Circuit 2 – Makarpura |

| Mr. Pankaj Chawla Manager ERDA (North) |

| Name of Employee |

|---|

| Mr. Laxman Bhekare Sr. Manager Admin |

| Mr. Rakesh A Patel Dy. Manager Appliance |

| Mr. Brijesh Sachdeva Manager Business Development ERDA (North) |

| Mrs. Sheetal Panchal Dy. Manager Cables |

| Mr. Nirav Taunk Manager Calibration |

| Mr. Umesh Soni Manager Electrical Diagnostics |

| Mr. Tejas Mistri Dy. Manager Energy Meter |

| Mr. Tirthashankar Vishwakarma Manager Impulse – Savli |

| Mr. Nitin Patel Dy. Manager Lamps & Luminaires & Solar |

| Mr. Pramod Patel Dy. Manager Maintenance (Civil & Electrical) |

| Mrs. Sneha Sheth Manager Solid Dielectrics |

| Mrs. Bhoomi Patel Dy. Manager Metallurgy |

| Mr. Shailesh Modi Sr. Manager Power Systems |

| Mr. Jeetendra Tahilwani Sr. Manager Transformers & Short Circuit 2 – Makarpura |

| Mr. Goutam Som Manager Switchgear & IP |

| Ms. Shefali Talati Dy. Manager TM4 Power Systems (R&D), Documentation |

| Mr. Kapil Sharma Dy. Manager Transformers |

| Mr. Nitin Doshi Sr. Manager ERDA (West) |

| Mr. Rajesh Marri Dy. Engineer ERDA (South) |

Where else are we located?

ERDA's

Code of Conduct

Our Mission and Values statement clearly declares that we shall achieve excellence in our areas of operation. Achieving this excellence is not possible if we do not act with Integrity, Honesty, Impartiality, Dignity, Loyalty and Pride for the organization. We must always ensure that we live out those values every day.

One of our primary objectives is to help our customers, meet quality standards for virtually any market in the world and protect them against risk by ensuring compliance with local, national and international laws. The accuracy and validity of reports and certificates that we provide and maintaining the trust and confidence of our customers, their customers and others impacted by our work, are therefore important factors which contribute to our success.

Our objective is to achieve excellence by virtue of competence through R&D, testing, calibration, training and information dissemination to improve quality and reduce cost of equipment, materials and services for electrical industries, utilities and users of electricity.

ERDA's

CLIENTS & TESTIMONIALS

ERDA collaborates with Manufacturers, Distribution & Transmission Companies, Power Plants & Process Plants across India and Globe to meet their requirement for laboratory evaluation and contract research. Our state of the art laboratories along with highly competent manpower ensures proper evaluation of our client’s products and to get greater market access. With “Customer First” centric approach, more than 10,000 customers are part of ERDA family.

Precision Wire India Ltd. HAPPY CLIENT

“….On behalf of our company, I would like to congratulate & appreciate you on being able to successful completion of testing & witness of CTC/PICC & CCCR. It is because of the hard work & dedication of your team that made it possible to get the project done on the pre-decided deadline. I wholeheartedly appreciate the way you worked on this project & made it a success. We express our sincere gratitude to you & your team. Thank you for your cooperation & looking forward to more years to come…”

GR Power Switchgear Ltd. HAPPY CLIENT

“…Thank you so much for your kind support and prompt response towards completion of testing and immediate reports. We appreciate your capability and commitment towards customer satisfaction.

Keep up the good work….”

Radiant Enterprise HAPPY CLIENT

“…Once again you have proved that ERDA team is one the best in business and it is only possible due to strong, experienced, and dedicated work force like yours. Please accept our appreciation and we look forward to have more business in future…’’

Hitachi Energy HAPPY CLIENT

“…We at Hitachi Energy India Limited Bengaluru would like to appreciate the excellent support offered by the ERDA team (HV Division) during the compliance testing of our products.”

Dakshin Haryana Bijli Vitran Nigam Limited HAPPY CLIENT

“…DHBVN is pleased to appreciate the efforts of ERDA team for providing the test report on very short notice in an emergency. We hope for the same cooperation & dedication from the officers be continued in future…”

Schneider Electric HAPPY CLIENT

“…Thank you ERDA team for your incredible work in Impulse testing. All of you provided good support. Thank you once again for your selfless assistance…”

R.B.Commercial Corporation HAPPY CLIENT

“…We are hereby very much thankful to ERDA- Savli team which have fully co-operated & helped us in getting our items tested & also providing immediately final test reports within a day by considering our emergency.

Truly entire ERDA – Savli team is so active & hard working in providing service to customer by considering their needs. We are thankful to entire ERDA team for their immediate help & co-operation to us…”

Agents and Agencys

Happy customers every year

Won Awards

New Listing Every Week

Subscribe

Figure 3: Prototype developed by ERDA